Fresnel Lenses

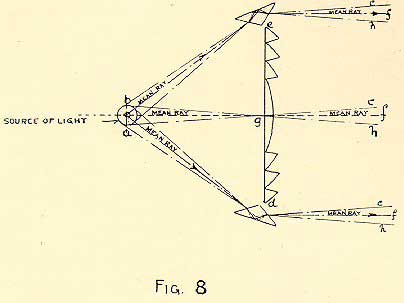

A Fresnel lens (pronounced fray-nel) is a type of lens invented by French physicist Augustin-Jean Fresnel.

Originally developed for lighthouses, the design enables the construction of lenses of large aperture and short focal length without the weight and volume of material which would be required in conventional lens design. Compared to earlier lenses, the Fresnel lens is much thinner, thus passing more light and allowing lighthouses to be visible over much longer distances..

Several manufacturers of lighthouse lenses commonly seen are:

- Chance Brothers & Co, Birmingham UK

- Henry Lepaute, Paris France which later became Barbier, Bernard and Turenne (BBT)

- Pintsch, Germany

- AGA, Stockholm Sweeden

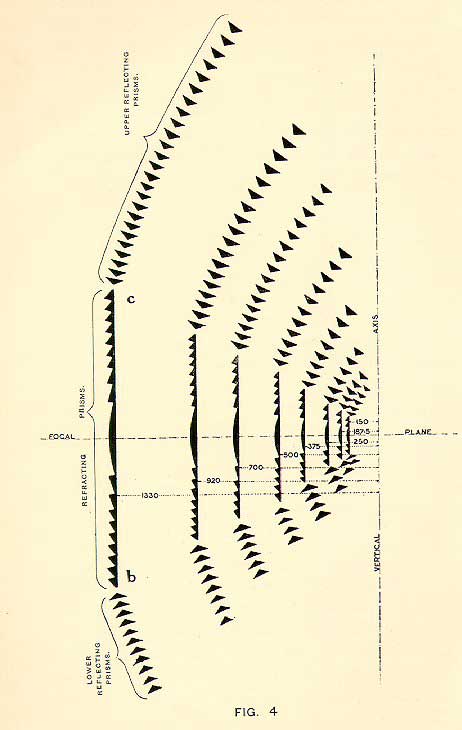

| Order | Focal Length |

|---|---|

| 0 Hyper-radial | 1,330 mm |

| 0.5 Meso-radial | 1,125 mm |

| 1st Order | 920 mm |

| 2nd Order | 700 mm |

| 3rd Order | 500 mm |

| 3rd Middle Order | 375 mm |

| 4th Order | 250 mm |

| 5th Order | 187.5 mm |

| 6th Order | 150 mm |

Fresnel's lighthouse lenses originally fell into six orders based on their focal length. The order of a Fresnel lens is approximately the dioptre or optical power of the lens. The dioptre is the reciprocal of the focal length of the lens in meters. A Fresnel lens with a focal length of 50 cm or 0.5 m would be classified as a third order lens.

Sir James Timmins Chance

CHANCE BROTHERS & CO Birmingham UK.

From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world.

Sir James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by fresnel lenses so as to increase the available light output; these cages, known as optics, revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution that the light flashes.

LIGHTHOUSE OPTICAL LENSES

Lighthouse optical lenses were commonly made from 2 distinct glass groups, crown and flint glass, crown glass commonly used up to the 19 century.Crown Glass

Crown glass is a type of optical glass used in lenses and other optical components. It has relatively low refractive index (≈1.52) and low dispersion. Crown glass is produced from alkali-lime (RCH) silicates containing approximately 10% potassium oxide and is one of the earliest low dispersion glasses.

As well as the specific material named crown glass, there are other optical glasses with similar properties that are also called crown glasses. Generally, this is any glass with Abbe numbers in the range 50 to 85. For example, the borosilicate glass is an extremely common crown glass, used in precision lenses. Borosilicates contain about 10% boric oxide, have good optical and mechanical characteristics, and are resistant to chemical and environmental damage. Other additives used in crown glasses include zinc oxide, phosphorus pentoxide, barium oxide, fluorite and lanthanum oxide.

Flint Glass

Flint glass is optical glass that has relatively high refractive index and low Abbe number. Flint glasses are arbitrarily defined as having an Abbe number of 50 to 55 or less. The currently known flint glasses have refractive indices ranging between 1.45 and 2.00.

The term flint derives from the flint nodules found in the chalk deposits of southeast England that were used as a source of high purity silica by George Ravenscroft, circa 1662, to produce a potash lead glass that was the precursor to English lead crystal.

Gustaf Dalén

Buoys & Beacons

Buoys and beacons are used as an Aid to Navigation (AtoN) and to assist lighthouses. They are found along harbours, inlets, channels, reefs and piers as markers.

Various company made these buoys and beacons, the most well known were AGA and Chance Brothers. Other lesser known companies include Pintsch Bamag, Henry Lapaute, Joyce and Brandt.

The AGA industrial company was founded in 1904. Initially AGA mainly focused on acetylene gas for railway lighting.

Soon the company employed inventive genius Gustaf Dalén as chief engineer and workshop manager whose inventions enabled AGA to grow rapidly.

It was the company’s inventions within lighthouse technology – the flashing beacon in 1905, the AGA compound in 1906, the sun valve and Dalén mixer in 1907 – which were to dictate the company's future.

By 1909 Dalén was president for the company. 1912 Gustaf Dalén was badly injured in an explosion which left him blind for life. He was still convalescing when the Swedish Royal Academy of Sciences awarded him the Nobel Prize in Physics for his “inventions of self-operating regulators, which in combination with gas accumulators can be used to light lighthouses and light buoys." He never regained his sight but he remained as the company's president for another 25 years, until his death 1937.

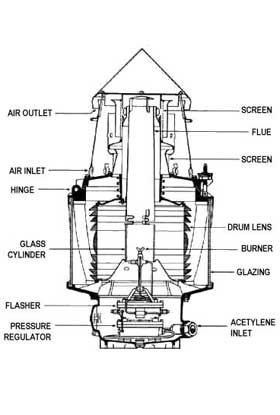

THE SUN VALVE

In 1907 Gustaf Dalén produced perhaps his most famous invention, the sun valve. This turns the beacon on and off using daylight. The first one was erected on Furuholmen’s lighthouse between Stockholm and Vaxholm. The design was so ingenious that many prominent contemporary engineers, including Thomas Alva Edison, doubted that the sun valve could work. The patent office in Berlin went so far as demand a special demonstration before it would approve the patent application.

The sun valve consists of a central, blackened, light absorbing metal rod surrounded by three gilt light-reflecting metal rods, all parallel with each other. In darkness all the rods are the same temperature and length. When dawn breaks the blackened rod absorbs light energy and acquires a slightly higher temperature than the shiny rods. The blackened rod becomes very slightly longer than the shiny ones triggering a device which cuts off the gas and switches off the lighthouse light.

When dusk falls, the blackened rod contracts, the gas valve opens and a small pilot flame lights the beacon. Combined with the flashing apparatus, the sun valve saves 94% of the gas compared with having the beacon alight all the time.